Contents

» Environmental issues» Main innovative features of vwt

» The new modular solution

» Follow the wind

» Take it easy

» The only things that never fail are the not installed ones

» Power generator main features

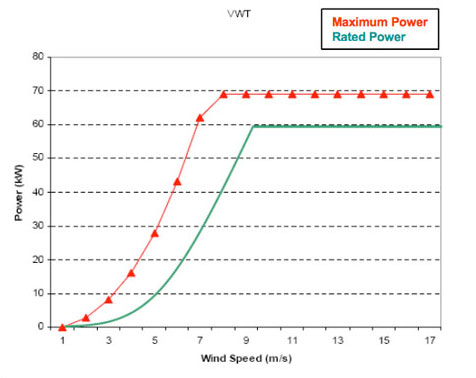

» 60kW VAWT ø18 x 24mt rotor

» Technical data

Business area

Environmental issues

- vwt is lighter

- material and energy saving in manufacturing process

- energy and emission saving in the transportation process

- energy and emission saving in installation

- energy saving in the whole product life-cycle

- vwt rotational speed is lower

- lower noise levels

- less criticale bird impact

Main innovative features of vwt

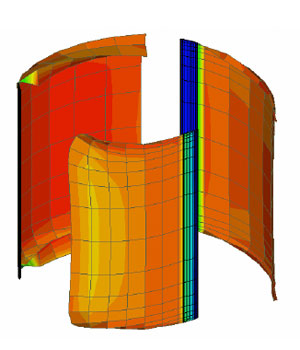

- it is designed and built in carbon fiber according to aerospace new technologies

- it can be delivered everywhere using standard 12 mt trucks

- it does not require lifting crane for assembly (wireframe tower)

- it is gearless, direct drive torque control

- it is lighter, component saving allows maintenance cost reduction

- short lead time for delivery

- innovative solutions for strong wind conditions (survival speed 50m/s)

- it does not require shutdown in stormy weather condition

- installation of a vwt cluster requires smaller interference distance

- air brake, pitch control, emergency mechanical brake

The new modular solution

HPD vertical wind generators (VWT) are cost effective, configuration is fully customizable according to local wind features and specific needs.Design and manufacturing technologies are derived from aircraft industry.

Follow the wind

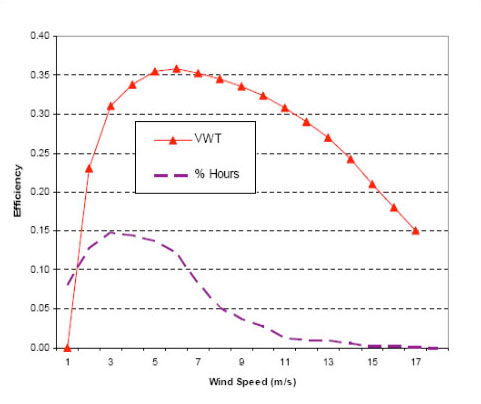

Tiro® pitch control follows wind direction.High efficiency can be obtained; even if unpredicted operational conditons occur, high continuity production is granted. Each blade produces torque regardless of wind direction.

Take it easy

Thanks to its modular design, VWT reduces power-up time.Short delivery time is obtained thanks to simplyfied construction, transport and installation.

The only things that never fail are THOSE THAT ARE not installed

The VWT design principle avoids complex gear and mechanics. Tiro® is based on a simple PLC device; it has been designed to have less than one fault per million cycles; in any cases, despite efficiency losses, the turbine does not stop energy production.Power generator main features

Generator Type: Permanent Magnet Machine.Control method: Vector Control

Torque & Speed Control (DTC).

Technical data

All specifications are indicative and fully customizable

All specifications are indicative and fully customizableSMVWT-0080-18.16-20 is 60kW generator with 18m blades, 16m rotor and 20m tower

SSWT are available in carbon fiber or aluminum.

| MWT | SMVWT | S2VWT | S1VWT | SSVWT | |

|---|---|---|---|---|---|

| OPERATIONAL DATA | Cut In: 3 m/s Design: 13 m/s Cut Out: 25 m/s |

Cut In: 2 m/s Design: 9*-12 m/s Cut Out: 25 m/s |

Cut In: 2 m/s Design: 9 m/s Cut Out: 25 m/s |

Cut In: 2 m/s Design: 9* – 12 m/s Cut Out: 25 m/s |

Cut In: 2 m/s Design: 9 m/s Cut Out: 25 m/s |

| BLADES | 3 x 24 m | 3 x 16 m 3 x 24 m(*) |

3 x 8 m | 3 x 8 m (*) 3 x 4 m |

3 x 3.5 m |

| ROTOR | 16 m | 16 m | 7 m | 4÷6m | 3.5 m |

| GENERATOR | 200kW | 60kW | 20kW | 6.5kW | 3kW |

| TOWER | 12÷16m | 12÷16m | 8÷12m | 8÷12m | 4÷8m |

| WEIGHT | Rotor: 1800 Kg Tower: 15000Kg |

Rotor: 800-1200 Kg Tower: 12000Kg |

Rotor: 650 Kg Tower: 1000Kg |

Rotor: 250 Kg Tower: 600Kg |

Rotor: 100 Kg Tower: 400Kg |

| CONTROLS | Tiro® Pitch Control Torque Control Speed Control |

Tiro® Pitch Control Torque Control Speed Control |

Torque Control Speed Control |

Torque Control Speed Control |

Torque Control Speed Control |